Matter of fact working with that material is just like working with cardboard.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your NNBS GMT900 Tahoe/Yukon Today?

- Thread starter phattyford

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

is it flexible enough? been a while since I had some of thst. but seem to remember it folded better than it bent haha.

As an Amazon Associate we earn from qualifying purchases.

Charlie207

Full Access Member

RockAuto shows the 6.2 Denali AWD and 5.3 selectable 4WD differential carrier as the same part number - https://www.rockauto.com/en/moreinfo.php?pk=14814485&cc=3305736&pt=15061&jsn=424Considering removal of the front diff (assuming easy, keep reading) in order for ease of oil cooler and trans cooler lines + a leaking axle seal on passenger side (slide hammer did not work so believe case may have to be split in half to access). Silly perhaps but bear with me.

My Denali is AWD - full-time, not the selectable hi/low 4WD unit. I've watched the below video a few times, and it seems (dare I say it?) easy... mind you this appears to be a 4WD front diff unit not AWD based on the wiring connection (*correct me if I'm wrong though).

Does anyone know if there any special considerations for removing the AWD front diff unit vs that of a 4WD one, which may/may not be contemplated by this video?

I assume the process for removal is the same for both.

Runfor5

Member

Oh interesting they are the same, I thought they would be different.RockAuto shows the 6.2 Denali AWD and 5.3 selectable 4WD differential carrier as the same part number - https://www.rockauto.com/en/moreinfo.php?pk=14814485&cc=3305736&pt=15061&jsn=424

I had enough of the old one left to lay it down and trace around it. what I used was rubber, so it didn't need to be to perfect. little thinner would been nice, I have a extra large cooler between the ac condenser and the radiator thou. the edges of the factory one stick in there about a half inch. bit of a squeeze.Is there a template anywhere?

Considering removal of the front diff (assuming easy, keep reading) in order for ease of oil cooler and trans cooler lines + a leaking axle seal on passenger side (slide hammer did not work so believe case may have to be split in half to access). Silly perhaps but bear with me.

My Denali is AWD - full-time, not the selectable hi/low 4WD unit. I've watched the below video a few times, and it seems (dare I say it?) easy... mind you this appears to be a 4WD front diff unit not AWD based on the wiring connection (*correct me if I'm wrong though).

Does anyone know if there any special considerations for removing the AWD front diff unit vs that of a 4WD one, which may/may not be contemplated by this video?

what tools did you use on the slide hammer?

I've not done the front, but I did the rear with these.. would they possibly save you dropping the axle?

Performance Tool W89326 Rear Axle Bearing Puller Set https://a.co/d/0eQOk7LA

As an Amazon Associate we earn from qualifying purchases.

I don't have an intercooler on my mustang with the Vortech, mainly because plumbing it is a nightmare with my intake and throttle body location. That's the main reason I use meth injection at the blower discharge. Plus the Vortech runs cooler than many other brand centrifical blowers to start with.

Earlier Fox bodied mustang setups are easier to run an intercooler, as well as the '96+ 4.6l models due to blower location.

I could run an intercooler if I switched to a fox style intake setup, which would include a different intake manifold and throttle body, but I like my Cobra intake manifold that's custom ported to my heads and the meth injection works for my needs. It's boost referenced and is variable, so under low boost it sprays less and increases as boost increases.

not thst meth isn't better in every way but didn't they sell a air to water cooler for the votech fox body kit years ago. I think they called it an after cooler?

seem to remember it worked pretty well and saved all that front mount routing

Runfor5

Member

Unsure of the specific tool, did this a couple years back at my parents place so whatever my dad had on hand. We were seeking to do it at the same time as replacing the wheel hub assembly on that passenger side (completed that part) but could not get the axle removed from the diff carrier. Our thought was perhaps there is a C-clip retainer holding it in as located inside the diff carrier. Maybe more 'brute force' would release it, but you'd risk damaging said clip that the factory put there for some reason (my view at least; could also be totally wrong about the clip and we're just weak LOL).what tools did you use on the slide hammer?

It's a super tiny weeping leak from the seal that's been there ever since I'm just trying to keep the truck's side of the garage floor clean

Considering removal of the front diff (assuming easy, keep reading) in order for ease of oil cooler and trans cooler lines + a leaking axle seal on passenger side (slide hammer did not work so believe case may have to be split in half to access). Silly perhaps but bear with me.

My Denali is AWD - full-time, not the selectable hi/low 4WD unit. I've watched the below video a few times, and it seems (dare I say it?) easy... mind you this appears to be a 4WD front diff unit not AWD based on the wiring connection (*correct me if I'm wrong though).

Does anyone know if there any special considerations for removing the AWD front diff unit vs that of a 4WD one, which may/may not be contemplated by this video?

For the passenger side axle seal the axle housing needs to be separated from the diff itself. Then the extension can be disassembled to replace the seal. This guy shows how it's done on a 4x4; your extension won't have the actuator but will probably be similar. I've seen other YouTubes of the process but didn't dig very deep this time.

And a similar one (first of two):

Last edited:

Grady_Wilson

Supporting Member

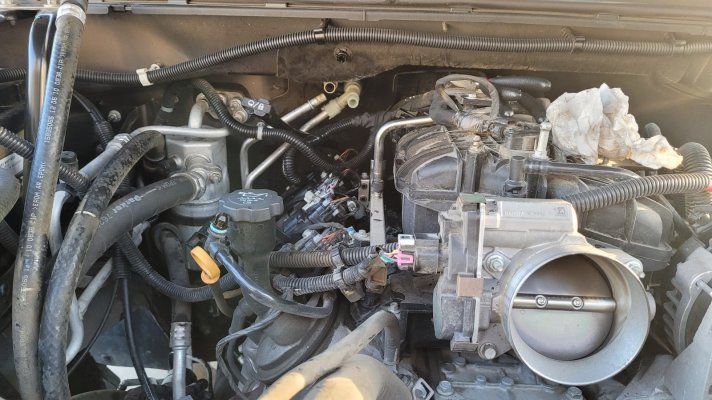

Not today, today, but late yesterday I replaced all of the heater hoses, both upper and lower radiator hoses and the thermostat.

I removed each O ring from the T connectors and sprayed them with silicone so they would slide on easier.

Also, both T's had a slight mold ridge that ran the length of the nipple so I used my jeweler's files and removed the ridges.

As you can tell by the discoloration of the white T connector, it was done and was most likely ready to fail.

I got way more beat up that I had planned but it is done.

Oh yea, I also did a quick clean up on the throttle body since I was staring at it the whole time.

I removed each O ring from the T connectors and sprayed them with silicone so they would slide on easier.

Also, both T's had a slight mold ridge that ran the length of the nipple so I used my jeweler's files and removed the ridges.

As you can tell by the discoloration of the white T connector, it was done and was most likely ready to fail.

I got way more beat up that I had planned but it is done.

Oh yea, I also did a quick clean up on the throttle body since I was staring at it the whole time.

Attachments

Last edited:

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 56

- Views

- 9K

- Replies

- 35

- Views

- 14K